Computer simulation of the injection molding process is advanced and allows the study of every detail of mold filling in 3D.

The design engineer can analyse the filling dynamics in thick and thin areas on screen, study the effects of gate position, thermal gradients in the mold and phenomena such as jetting and binder segregation.

Designers can also optimise the kinetics of mold filling and determine shrinkage and distortion of the green compact relative to the mold dimensions.

A careful analysis and optimisation of the mold cavities can reduce design time and cost while significantly improving yield and quality.

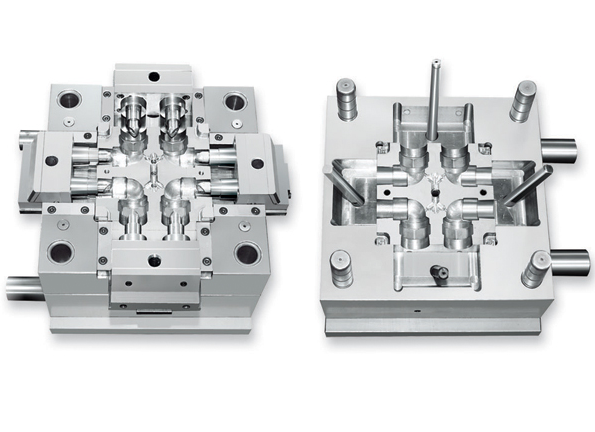

Figures1

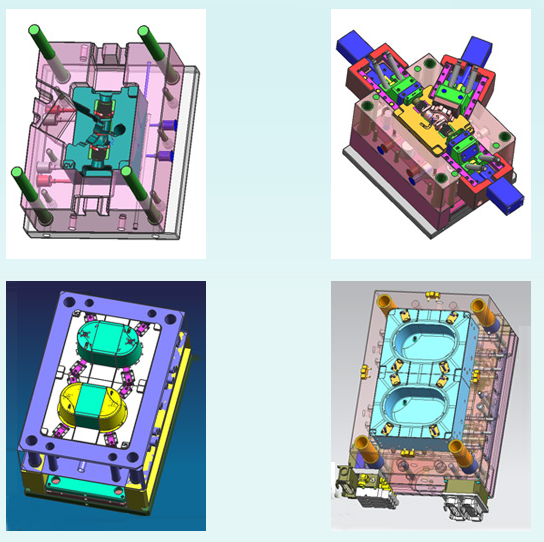

Figures2

Tel.:+86-760-23453788 Fax.:+86-760-23453789 E-mail: sales@sintspm.com

Address: South Industrial Zone,Fusha Town,Zhongshan City,Guangdong Province,China

copyright@2007-2022@Zhongshan Sints Powder Metallurgy Co.,Ltd sitemap

High-Quality Precision MIM Parts from a Trusted China Manufacturer